we enable our customers to reduce expenses by retrofitting existing equipment, improving their productivity

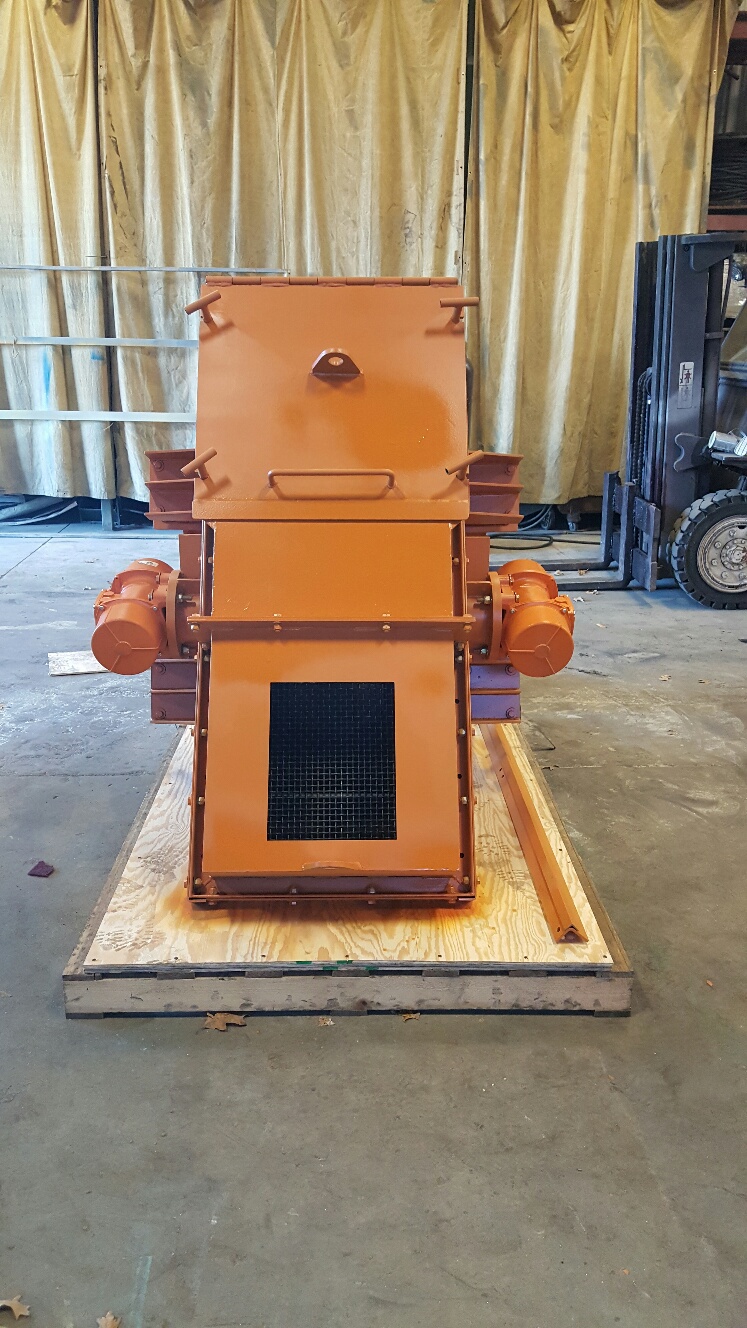

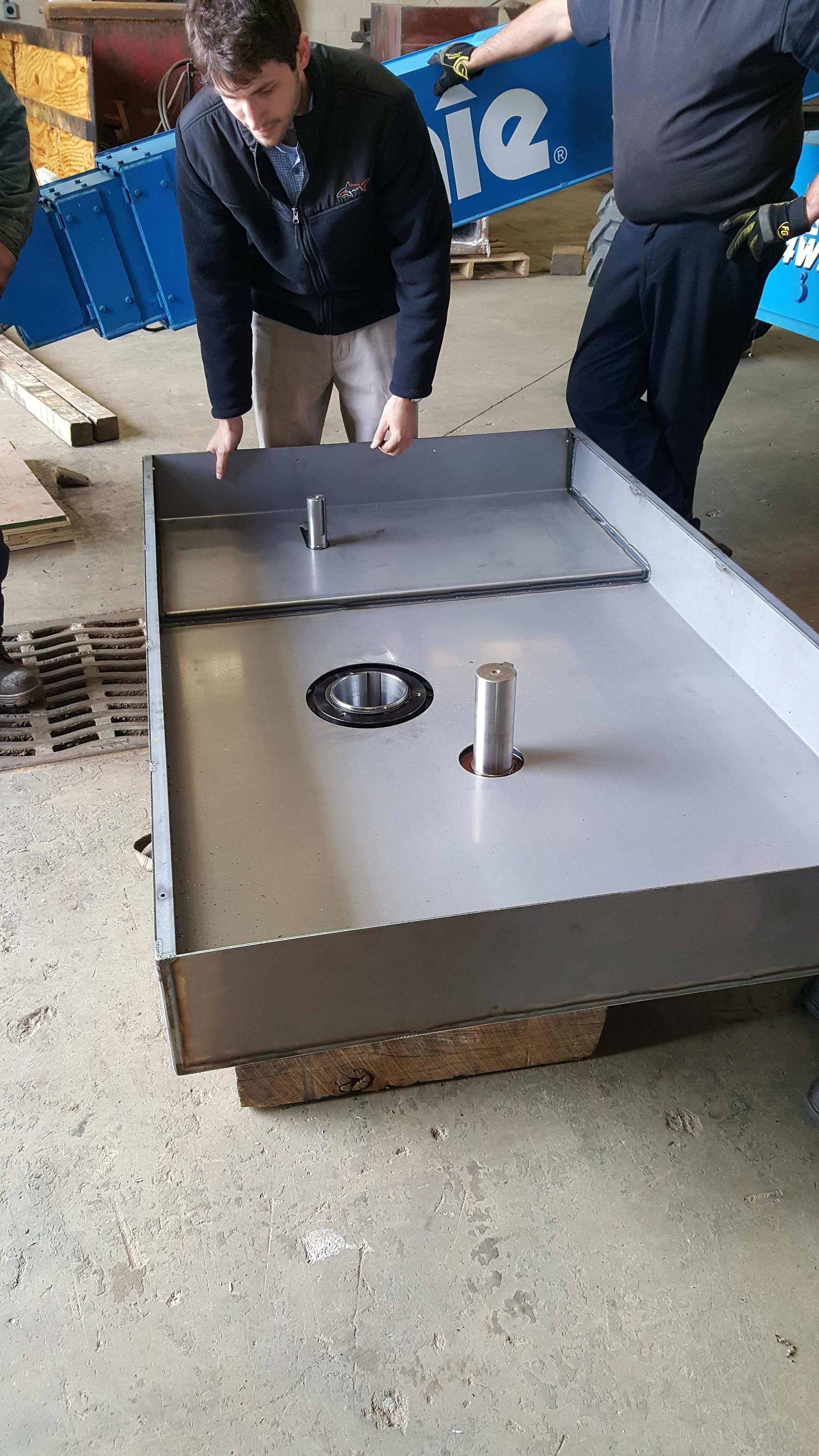

Vibratory Feeder and Load Zone

Project Number: PJ15-016

Location/Industry: Manufacturing

Materials Handled: Roofing/asphalt granules

Customer Requests/Problems:

- Large amounts of dust coming from load zone.

- Spillage at conveyor tail.

- Material build-up on conveyor components causing premature wear.

Actions Taken:

- 3D laser scan of work site.

- Provided concept drawings and models.

- Provided full-design drawings overlaid with scans for accuracy and fit.

- Listed parts for purchase.

- Fabricated custom vibratory feeder.

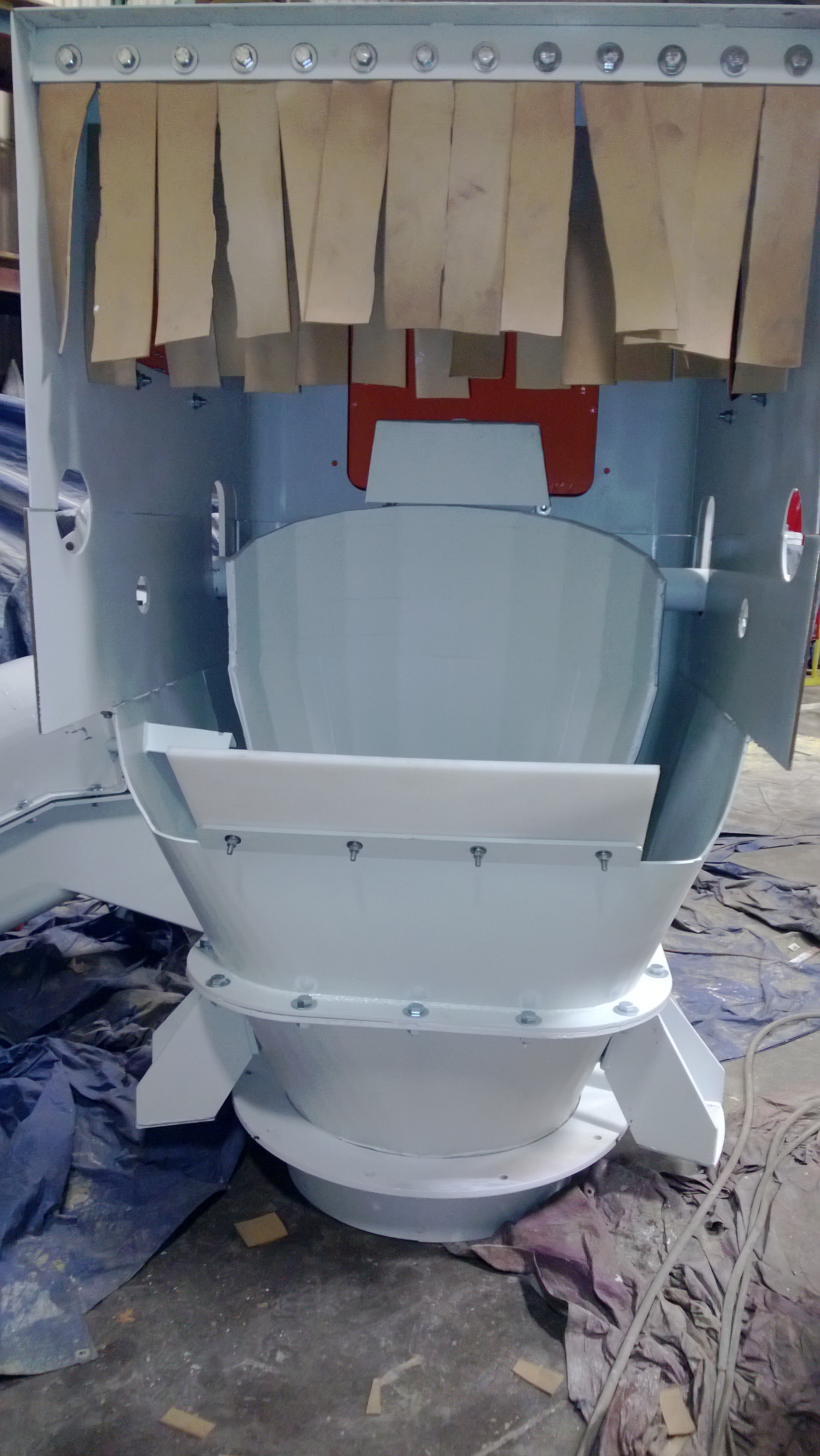

- Fabricated custom load zone.

- Provided installation instructions and support.

Return on Investment:

- Reduced splash loading by centering load point and direction.

- Higher and longer load zone reduced dust and spillage.

- Reduced clean-up time - labor costs.

- Increased clean operation time.

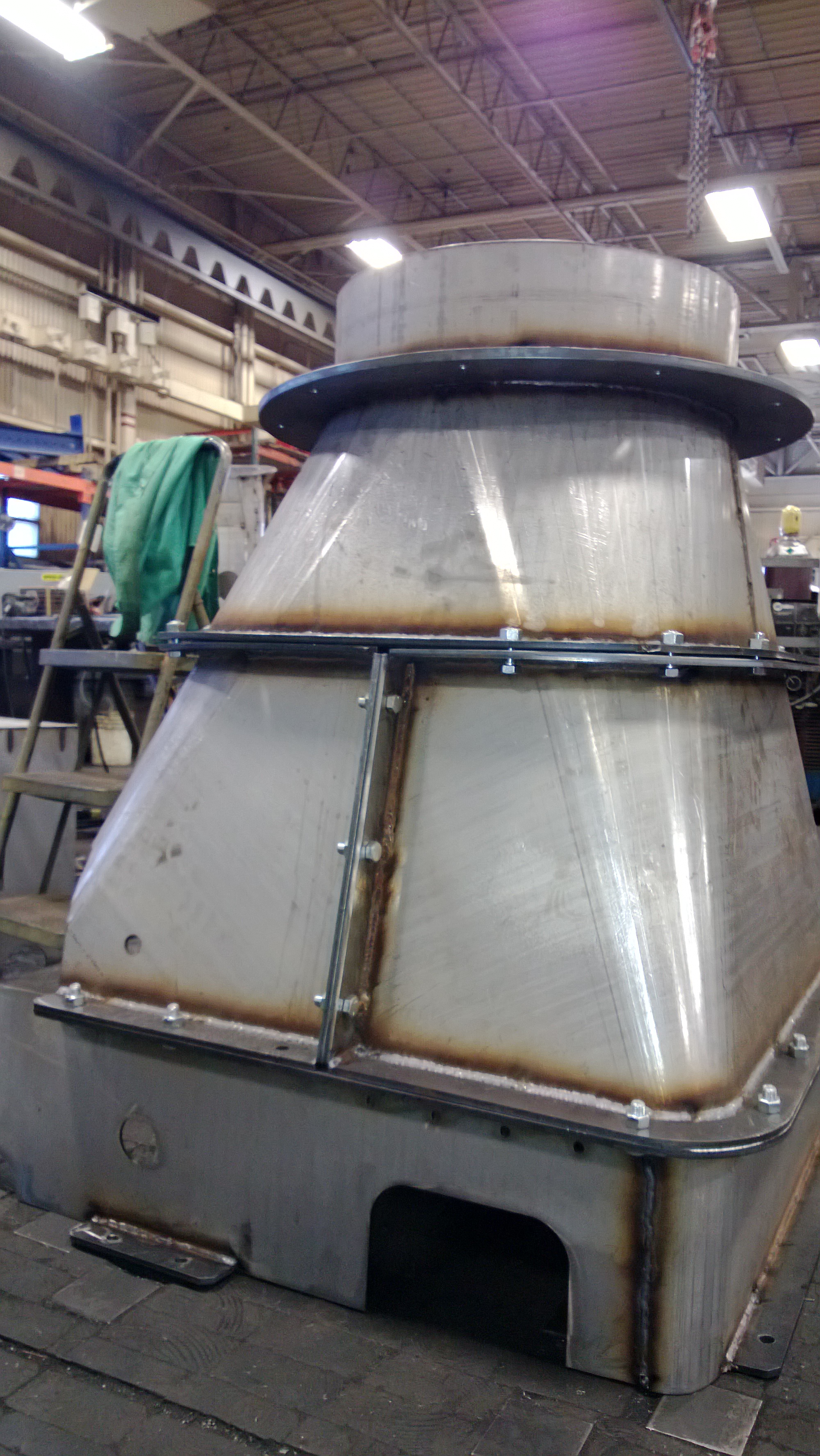

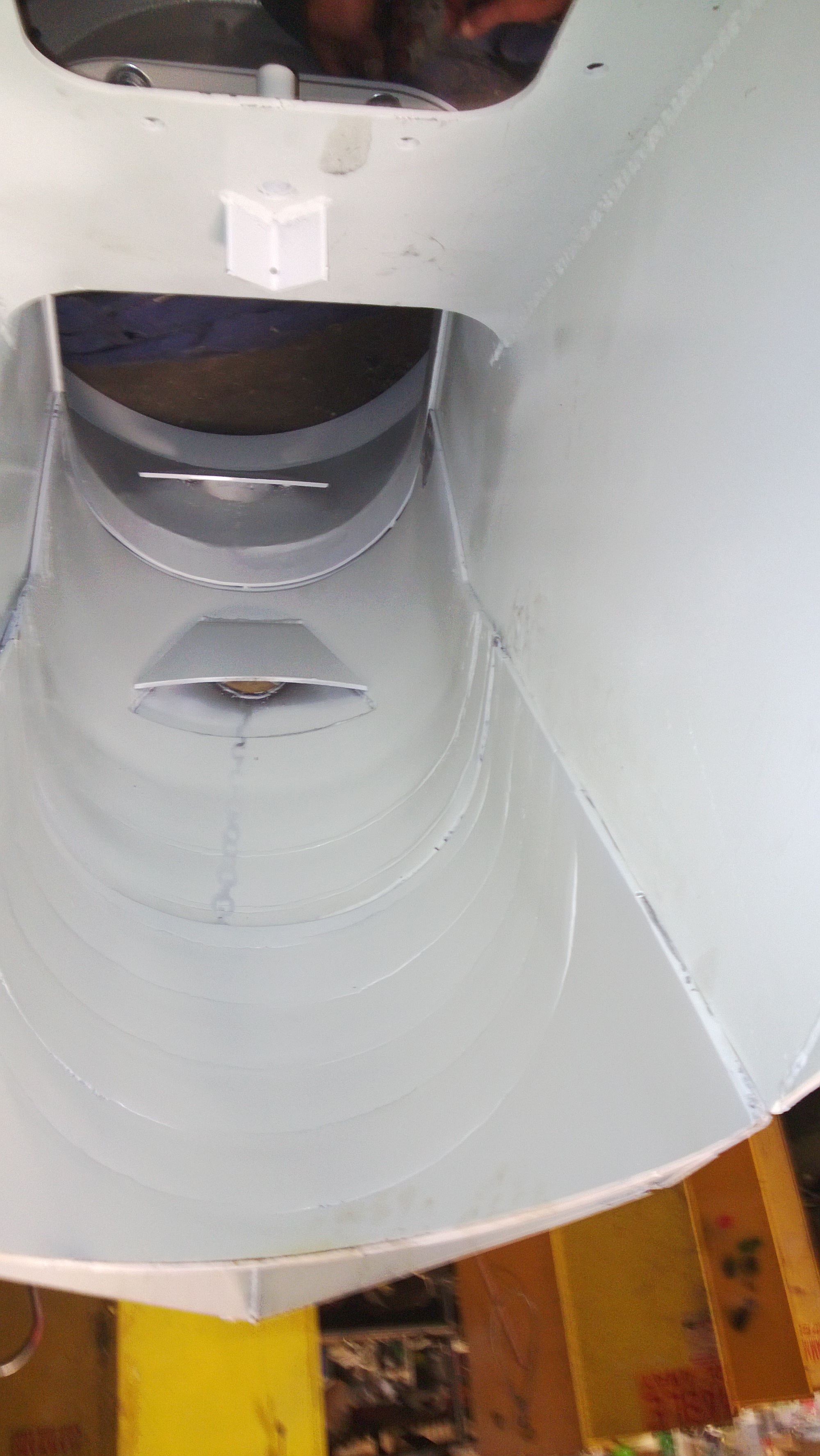

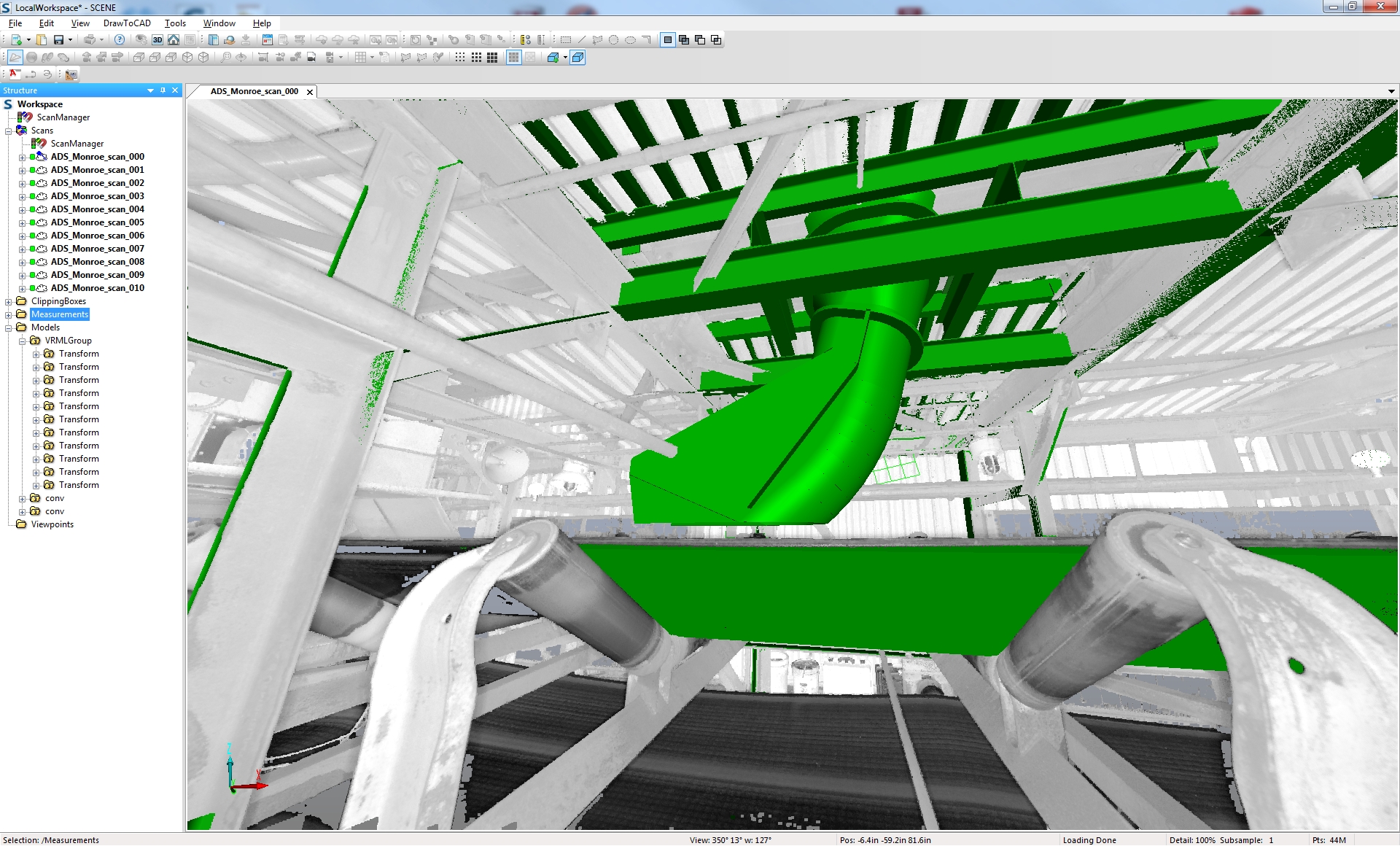

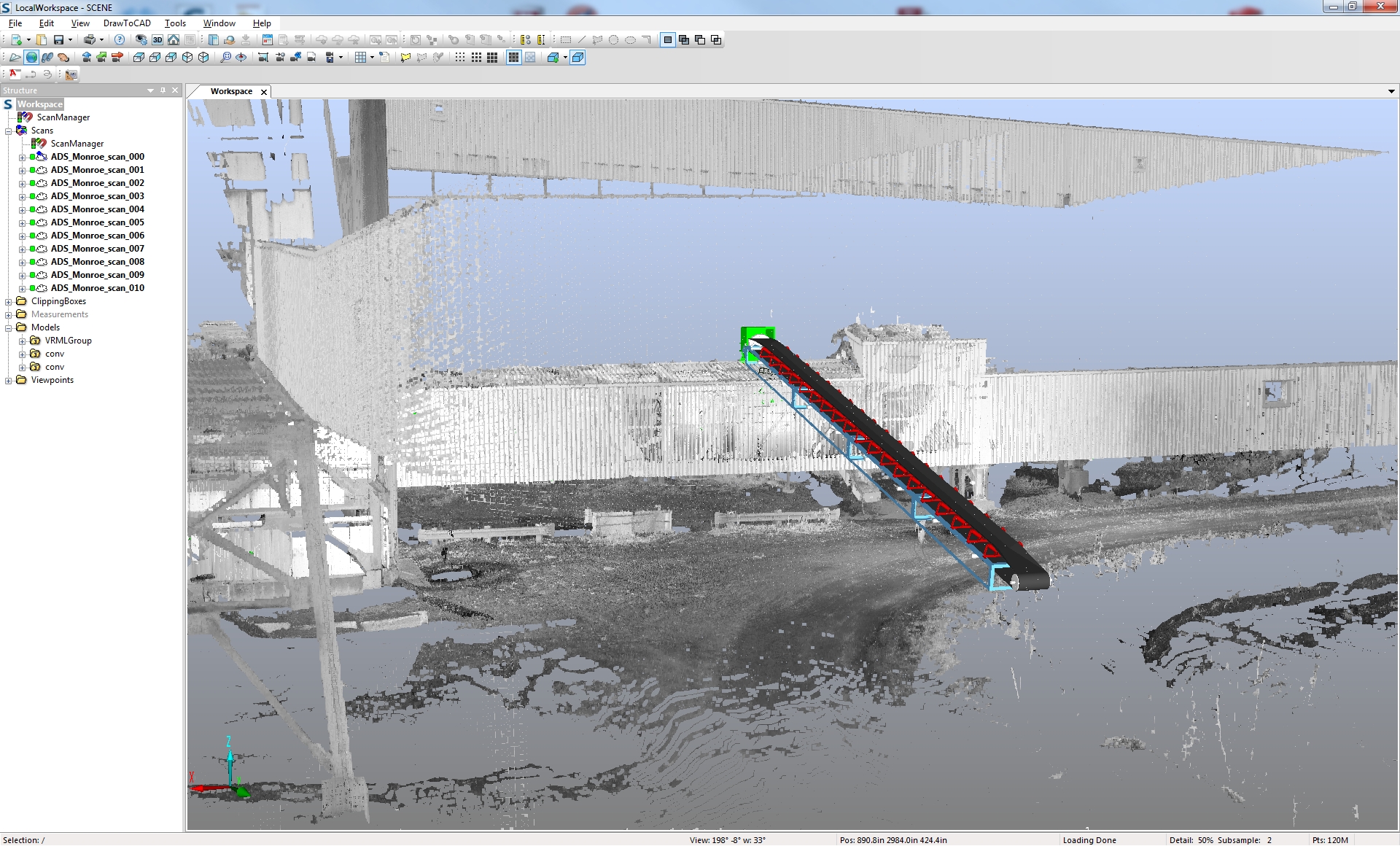

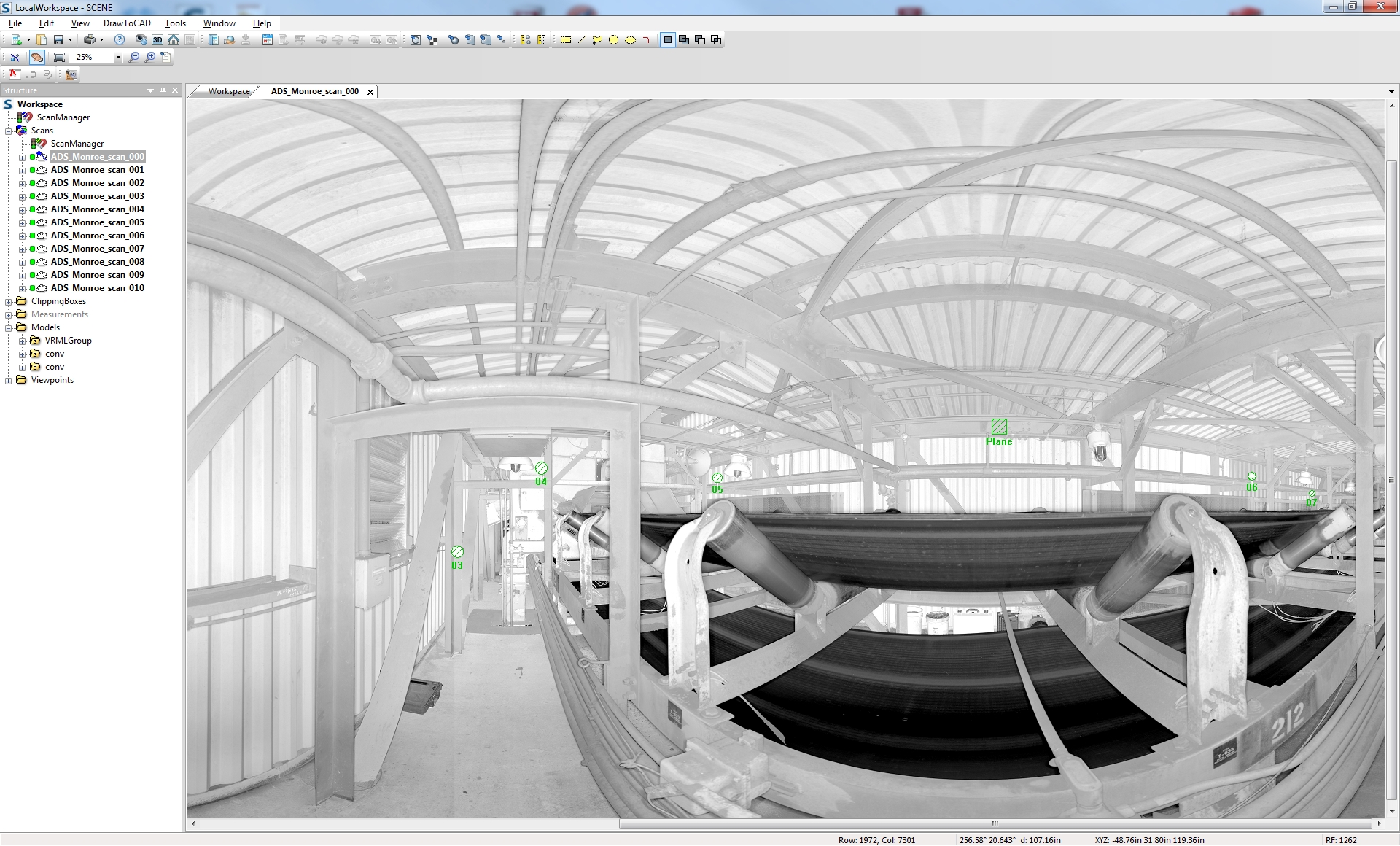

Transfer Chute

Project Number: PJ13-033

Location/Industry: Power Generation

Materials Handled: Petroleum Coke

Customer Requests/Problems:

- Develop a temporary system that matches up to their exiting system and deliver material at the desired rate & percentage.

- Make the delivery to the main plant feed conveyor without dust or fugitive material.

- Design with the ability to adapt to a permanent system.

Actions Taken:

- Site survey.

- Discovery process.

- 3D laser point scan.

- DEM flow analysis.

- 3D solid modeling design.

- Check modeled design with existing structure using scans.

- Visual site viewer created.

- Fabrication & pre-assembly before outage.

- Installation.

Return on Investment:

- Existing structural interference was identified early with 3D scanning overlaid with models, saving critical outage downtime.

- Installation was an exact fit and was completed in a two hour outage.

- Optimal material flow in all conditions.

- Minimal dust and fugitive material.

- No additional maintenance to date.

Conveyor Drive & Motor

Project Number: PJ15-061

Location/Industry: Power Generation

Materials Handled: Limestone

Customer Requests/Problems:

- Conveyor drive and motor strength was insufficient for the amount of material being loaded onto the belt.

- Conveyor belt could not be started from a dead stop due to the large amount of loaded material.

Actions Taken:

- Provided drive components:

- Shaft mounted gearbox

- 10 hp motor

- Guarding

- Pre-assembly of gearbox, back stop, bushings, sheaves, v-belts, guarding and torque arm.

- Provided drawings for reference and installation instructions.

Return on Investment:

- Low risk of incorrect parts and missing pieces.

- Ability to start and stop the conveyor.

- Ability to convey required amount of material without damaging the motor.